Aurora-VT (Vehicle Testing)

Aurora Optimizes the Vehicle Testing Process by Selecting the Best Vehicle Configurations to Minimize the Vehicle Count & Overall Schedule Duration.

To optimize a major automobile manufacturer’s vehicles for both nondestructive and crash testing, Stottler Henke infused its intelligent planning and scheduling system, Aurora, with domain-specific heuristics used in the vehicle task planning process, resulting in a circa 10% decrease in the total number of vehicles needed to complete the same test/crash suite within the same time constraints. That is, Aurora-VT (Vehicle Testing) meets the same goals as the auto manufacturer already set, but with about 10% fewer vehicles; Aurora-VT has also increased the capability and ease to ask ‘what-if’ questions to further improve the schedule: for example, how much faster the test suite could be completed with only 5% fewer cars, or how many cars would be needed to complete the suite 15% quicker. Some new vehicle models may require over 100 vehicles; to date, Aurora-VT has saved over 10 vehicles, which translates into millions of dollars in savings for only one new vehicle model.

Aurora-VT is fueled by sophisticated artificial intelligence that optimizes automotive test schedules in order to complete work in a given time window while minimizing the total number of vehicles required. Aurora determines how to use fewer vehicles while providing improved transparency into what types of delays will affect the actual end date of the test suite, which not only allows for fewer vehicles to be built, but for enough safety to be built into the schedule so that the project goals of completing all tests within the desired timeframe, and, at the end of the day, verifying the vehicle performs as designed, can be achieved even with the inevitable unexpected events that will occur during the testing process.

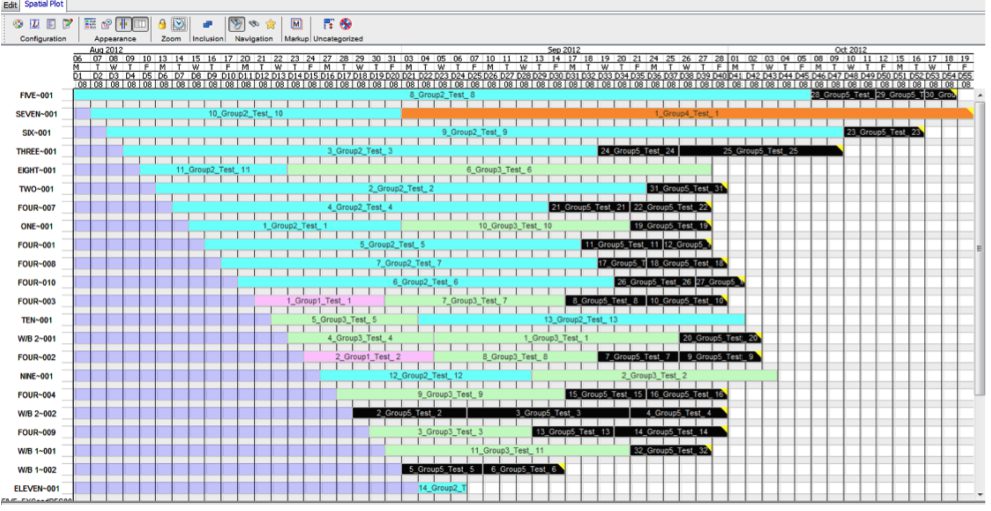

Striping indicates viable vehicle types for each task. Tasks with just a corner tag can only use one vehicle type, multiple corner tags indicate greater flexibility.

BACKGROUND

This Motortrend article, 2016 Honda Pilot Named Top Safety Pick + by IIHS (W/Video), describes aspects of vehicle testing, including an informative video with a vehicle impact test.

PUBLICATIONS

Ludwig, J., Kalton, A., Richards, R., Bautsch, B., & Walker, L. (2024). Lessons Learned from a Schedule Optimization Tool for Prototype Vehicle Testing. Presented at the KEPS 2024 Workshop at the International Conference on Automated Planning and Scheduling. Banff, Canada, June 2-3 2024. Paper.

Ludwig, J., Kalton, A., Richards, R., Bautsch, B., Markusic, C., & Jones, C. (2016). Deploying a Schedule Optimization Tool for Vehicle Testing. International Conference on Automated Planning & Scheduling (ICAPS) 2016. London, U.K. June 12-17, 2016. Paper. Presentation.

Ludwig, J., Kalton, A., Richards, R., Bautsch, B., Markusic, C., & Schumacher, J. (2014). A Schedule Optimization Tool for Destructive and Non-Destructive Vehicle Tests. Proceedings of the Twenty-Sixth Annual Conference on Innovative Applications of Artificial Intelligence (IAAI 2014). Paper. Presentation.

Example of a smaller test suite

Example of a larger test suite; note that there is a variable build pitch for the test vehicles being constructed