Save Time. Cut Costs. Aurora.

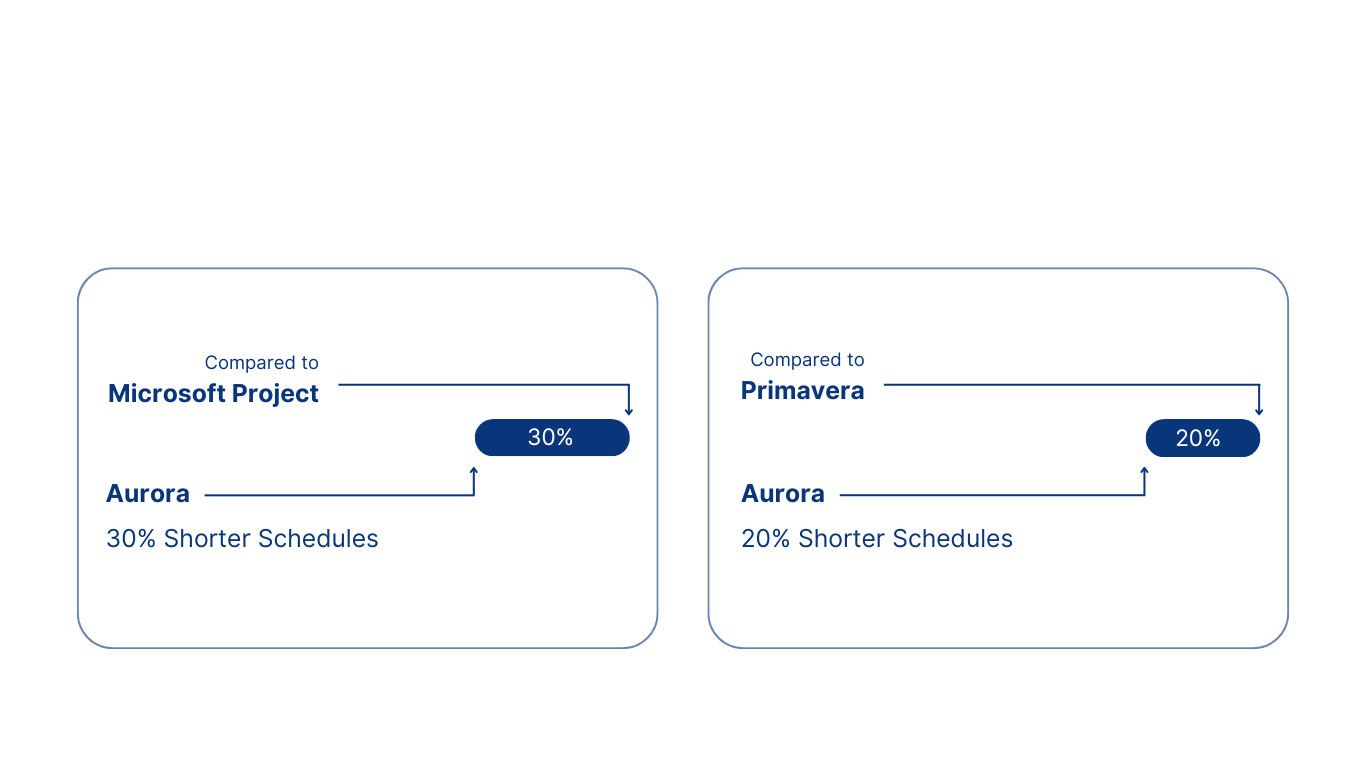

Aurora™ is the most advanced Intelligent Planning and Scheduling Solution available on the market today. It utilizes advanced artificial intelligence to tackle scheduling problems with complex constraints by incorporating the judgment and experience of expert human schedulers. Originally developed for NASA, Aurora is particularly effective when applied to large projects with complex constraints and resource requirements. Over the last 25 years, an increasing number of organizations have chosen Aurora to manage operations more efficiently than any other system it has ever been compared to, and for Project Portfolio Management (PPM), Aurora has proven vastly more powerful than any other solution including Microsoft Project and Primavera P6.

Aurora™ outperforms conventional software solutions.

AURORA TAKES A DIFFERENT APPROACH

Most systems use simple rules to select and schedule activities and assign resources to carry them out. However, these schedules are often far from optimal. Aurora solves complex problems more effectively by encoding and applying sophisticated scheduling knowledge and user-supplied, decision-making rules, along with complex constraints and resource requirements.

Furthermore, Aurora encodes attributes of individual tasks, groups of tasks, resources, resource sets, and constraints. Aurora’s built-in and user-supplied decision rules produce better schedules by considering these attributes at key scheduling decision points such as determining which task to schedule next, assigning the best time and resources to each task to optimize the overall schedule, and handling situations in which some resources are not available when the task is scheduled.

AURORA IS USER FRIENDLY

Aurora’s graphical user interface enables users to enter domain-specific scheduling knowledge and requirements quickly and easily. Interactive graphical displays enable users to visualize and edit the schedule’s resource allocations and temporal relationships among activities. More than that, Aurora automatically detects and highlights scheduling problems such as unresolved conflicts.

For further details, view this presentation on Intelligent Scheduling. If you’d like to know what our clients are saying about Aurora, you can view our customer testimonials. If you still don’t believe we can help reduce your project turnaround times, then fill out the form below to find out more.

AURORA OFFERS STRATEGIC BENEFITS

Aurora focuses on resource requirements and temporal scheduling in combination, providing more efficient use of available resources resulting in shorter project turnaround times. Since the same amount of work is completed in less time, this greater throughput results in increased cost savings when compared to other scheduling software alternatives.

Aurora complex constraint support allows planners to develop more realistic project models that adapt more realistically during execution. Aurora also supports forward and backward scheduling as well as mixed mode scheduling so you can have your projects scheduled according to your needs. More importantly, Aurora’s schedule unique explanation reports show you why each task was scheduled where it was scheduled. Aurora is also designed to allow extensive customization, meaning that it can meet varying needs and priorities.

Other Unique Capabilities of Aurora:

Concurrent Constraints

These allow the user to specify that two jobs need to happen at the same time in the schedule.

Special Manufacturing/Shift Control Properties

This allows the user to specify a preference order when defining a set of rouces that are mostly interchangeable.

Exclusivities

These allow the user to specify that a job cannot happen at the same time as another job or class.

Stable Schedule Mode

Aurora provides a mode that will prefer to retain the previous schedule, with the minimum updates necessary to incorporate emergent work or updated resource availability. This permits updates to take new data into account while avoiding churn.

Capacity Change Constraints

This allows the user to specify a relationship between a task and a resource. Some tasks may make a resource available (e.g., adding a space zone that can subsequently be used for work), while others may make a resource unavailable (e.g., installing panels that block access to a space zone).

Monte Carlo Simulation

This takes advantage of duration distribution information to simulate multiple executions of the schedule to show how things are likely to play out. This gives the IEs insight into how brittle their scdedule is, how likely it will be to run late, etc.–and from there, try to make their schedule more robust and stable.

Preferred Resources

This allows the user tos pecify a preference order when defining a set of resources that are mostly interchangeable.

Special Downstream Work Analysis

This ensures that work is started if more complex downstream work depends on it.

Sensitivity Analysis

This takes advantage of duration distribution information to explore what would happen to the schedule if certain key jobs are faster than expected or slower than expected.

Customer Success Stories

Automobile Industry

A major automobile manufacturer selected Aurora to optimize its vehicles for destructive and non-destructive crash testing.

Mass General Hospital

Aurora is used by the Massachusetts General Hospital to schedule its medical residency program. Aurora reduces the time and effort needed to generate schedules and provides better support for the hospital’s complex staffing needs.

Pfizer

Aurora-ProPlan is a component of the Intelligent based Manufacturing (IbM) initiative at Pfizer. It adds capabilities necessary to perform pharmaceutical production optimally.

Pilot Training

Alaska Airlines uses Aurora to schedule their pilot training program. Aurora coordinates training across students in a class, prevents significant gaps in training, blocks out maintenance times, and more.

Audit Scheduling

TenA Company, founded in 1982, is the premier mortgage quality control service in the United States, assisting thousands of mortgage lenders each year. Among their carefully vetted personnel, are counted Legal & Compliance experts and a QC Solutions team.

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries (MHI) is using Aurora to accelerate its production of Boeing 787 composite wing boxes.

General Dynamics Electric Boat

Aurora is being leveraged by General Dynamics Electric Boat (GDEB) for the scheduling of various aspects of submarine construction. In this way, GDEB is provided with intelligent scheduling capabilities not available in other project management software.

The Boeing Company

The Boeing Company uses Aurora to prioritize the production of the Boeing 787 Dreamliner™. Aurora’s dynamic assembly schedule adapts to real-time production variations, so Boeing can produce aircraft as efficiently as possible.

Los Alamos National Laboratory

Los Alamos National Laboratory (LANL), selected Aurora for its unique capabilities including intelligent resource scheduling to improve their project management, offering both increased throughput and greater project transparency.

United Space Alliance

The United Space Alliance included Aurora in the design of Temporis, a scheduling system targeted for use by NASA crew members on board next generation spacecraft during deep space missions.

Dental Student Scheduling

New York University (NYU) College of Dentistry uses Aurora to create dental student schedules, including scheduling student courses while accounting for clinical rotations, course requirements, and special events.

NASA: Space Shuttle

Aurora/AMP, which was in service for 18 years at NASA’s Kennedy Space Center, generated short- and long-term (10-year) schedules for ground-based activities that prepared and refurbished Space Shuttles before and after each flight.

Navy Submarine Support

The US Navy has selected Aurora-CCPM™ software to schedule maintenance operations at the Naval Submarine Support Facility (NSSF).

Space Force Satellite Scheduling

The Aurora intelligent scheduling framework has been applied to Space Force Satellite Control Network (SCN) scheduling to create an automatic scheduling and deconfliction capability called MIDAS.

Korea Aerospace Industries Ltd. (KAI)

Aurora helps Korea Aerospace Industries (KAI) schedule production of composite parts for Boeing’s Dreamliner.

Bombardier Learjet

Aurora helps Bombardier Learjet schedule their airplane assembly operations more quickly, so they can handle production rate changes and component delivery delays more effectively.

Would you like a FREE Demo? Contact Us

Please enter your contact details, company name and a short message below and we will answer your query as soon as possible.