Boeing Frontiers article

Night moves: Jetliner production rates are going up, and Boeing teams are picking up the pace

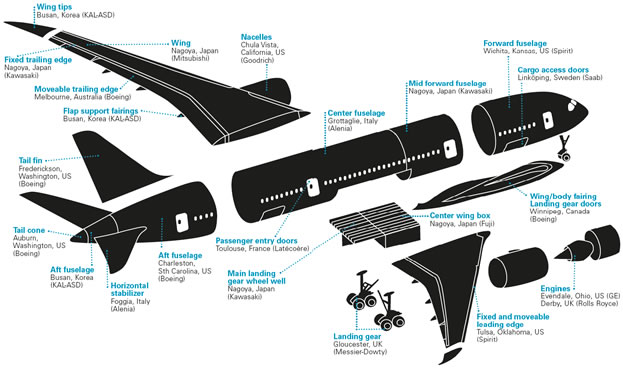

The Boeing Frontiers article provides some aspects of production/manufacturing that makes efficient scheduling so challenging. Note that the items discussed, including tooling, scaffolding, people, the changing amounts of physical space during production all have to be modeled and intelligently optimized to maximize the efficiency of aircraft production.

Aurora is the world’s most efficient system for maximizing the throughput of production/manufacturing environments due to its ability to optimize the utilization of limited human and non-human resources, and all the interacting constraints. View the Boeing Frontiers article.

Press Release

Media Contact:

Jim Ong

650.931.2710![]()

FOR IMMEDIATE RELEASE

Stottler Henke to Facilitate Assembly of Boeing 787 Dreamliner

for Boeing’s newest commercial airliner

SAN MATEO, Calif., May 29, 2007 – The Boeing Company (NYSE: BA) contracted with Stottler Henke Associates, Inc. (www.stottlerhenke.com) to develop a version of Stottler Henke’s Aurora™ intelligent scheduling software specifically to help Boeing manage certain aspects of the process of building the Boeing 787 Dreamliner™ commercial airliner, which is due to market in 2008. Aurora is a configurable scheduling engine that enables organizations to plug in components that provide the domain-specific expertise needed for each unique type of scheduling task.

The Boeing engagement is one of several Aurora-related projects now under way at Stottler Henke. The firm also is developing for the United Space Alliance (USA) an in-flight version of Aurora for proposed use on board the United States’ next-generation manned spacecraft. The system is designed to be used by astronauts to schedule their activities on the Crew Exploration Vehicle (CEV), due to launch in 2008. Aurora is currently in use at NASA at the Kennedy Space Center.

The Aurora version for Boeing will prioritize factory production tasks by balancing resource capacities with manufacturing requirements and constraints. The result is a dynamic assembly schedule that will adapt to real-time production variability and allow Boeing to execute the plan as efficiently as possible.

“The greatest consideration in airplane assembly scheduling is the scale of the problem, and the tangle of inter-related constraints which make it extremely difficult to resolve conflicts,” said Richard Stottler, president of Stottler Henke Associates. “We’re gratified that Boeing recognized in Aurora a uniquely capable solution for this massive scheduling challenge.”

Aurora is a sophisticated scheduling system that combines a variety of scheduling techniques, intelligent conflict resolution, and decision support. The software’s scheduling decisions take into account resource requirements, a variety of constraints, and any pertinent domain knowledge.

Once Aurora has created a schedule, it displays it in a series of graphical images that allow the user to see the scheduled activities, resource allocations and the temporal relationships among the activities. This display also allows the user to edit the schedule directly, intuitively, and easily. Aurora’s analytic capabilities help the scheduling team understand why the software scheduled the way it did, so the team can focus on those parts of the production plan that could result in schedule cycle improvement if streamlined.

Founded in 1988, Stottler Henke Associates, Inc. applies artificial intelligence and other advanced software technologies to solve problems that defy solution using traditional approaches. The company delivers intelligent software solutions for education and training, planning and scheduling, knowledge management and discovery, decision support, and software development. Stottler Henke’s clients include manufacturers, retailers, educational media companies and government agencies. In 2006, Stottler Henke was the subject of a NASA “Hallmarks of Success” video profile for its work developing and later commercializing advanced planning and training software systems. Stottler Henke received a 2004 “Brandon Hall Excellence in Learning” award for innovative technology. For the past four consecutive years, Stottler Henke was named one of the “top 100” companies making a significant impact on the military training industry by Military Training Technology magazine, and in 2005 received a Blue Ribbon recognizing it as a company that leads the industry in innovation. Web: https://www.stottlerhenke.com Email: